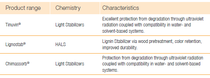

The demand for paints and coatings that cover ever-greater surfaces per liter without compromising long-term protection continues to rise. Avoiding light- or heat-induced degradation of coatings for extended periods involves mastering a complex array of challenges. As a pioneer in this special area of coatings technology, BASF draws on decades of experience and the broadest, most diverse portfolio of light stabilizers in our industry. The range can be roughly divided into two main technologies: filters that block ultraviolet radiation and scavengers that “hunt down” and eliminate free radicals within the coating. As diverse as our solutions are, they all serve to enable coatings that protect, beautify and extend the service life of UV-sensitive substrates.

One of the highlights is our innovative Tinuvin® DW (ECO) line for water-based applications. The light stabilizers are based on a proprietary technology that encapsulates the active agents in an acrylic copolymer matrix, termed Novel Encapsulated Additive Technology (NEAT). The solvent-free additives feature low viscosity, freedom from EUH 208 labeling and long-term storage stability without sedimentation or phase separation.

NEAT-based UV absorbers are not only ideal for low�and zero-VOC formulations, but also easy to incorporate. They disperse homogeneously into water and/or water-based paint, and can be added in the final stage of the production process under normal stirring conditions without special equipment or dispersing aids like emulsifiers or co-solvents. Coating properties such as color, gloss, transparency or resistance to wear are left unaffected.

For UV protection coupled with enhanced gloss and color retention in solvent-based formulations, we offer the Tinuvin® 5000 series. These easy-to-handle additives are compatible and soluble in most solvent-based systems, and meet all performance demands of automotive, industrial and architectural applications. The series also contains subgroups with specific properties such as suitability for wood, plastic and metal substrates or exceptionally high thermal stability.

The Lignostab® solutions provide highly effective long-term UV protection in wood-impregnation systems.

Regardless of what type of system you wish to formulate and issue you face, we can support you with solutions that significantly enhance the performance efficiency and service life of your final product. Our facilities dedicated to innovation in light stabilizers and antioxidants at our main headquarters in Germany as well as in Switzerland, we are in a unique position to set industry standards. And thanks to our deep understanding and close monitoring of regulatory developments, we can also provide invaluable compliance support.