Dispersions & Resins

Licity® – the secret ingredient for Li-ion batteries

Licity® boosts batteries – mechanical testing of anodes

Profound tests for reliable results

The quality of the coating is characterized by mechanical performance features. In order to judge those, BASF conducts primarily two tests which both need to be passed by the anodes: the bending test and the 90 degree peel test.

Bending Test

Bending test

The bending test is a means of assessing the flexibility, among other things. The sample is bent over metal rods of varying diameters. If there are no cracks or separations, the test is passed.

90 degree peel test

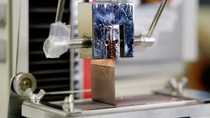

90 degree peel test

The 90 degree peel test unveils adhesion and cohesion of the coating. With constant velocity, the testing machine determines the force which is needed to separate the coating from the copper foil.

Licity® boosts batteries

With both tests passed, the samples are ready for the next step: they can be sent to customers or our own EC testing lab.

Are you excited in leveraging our expertise? Please reach out to Christian Brand, our Licity® expert. We are looking forward to hearing from you.

“Licity® binders are an easy way for battery manufacturers to boost their cell performance. But there is more: Licity® is additionally the promise to support our customers along the complete production process from raw materials to cell testing.”