Dispersions & Resins

Functional Packaging Coatings

We offer a range of water-based binders for formulating functional packaging coatings for substrate enhancement and functionality. The Joncryl® HSL product line offers solutions for heat seal lacquers in various applications, e.g. dairy lidding and pharma blisters. Our water-based emulsions for primers and lacquers are used in aluminium dairy pot lidding applications.

Our water-based Joncryl® Solutions

BASF offers numerous solutions, e.g. from the Joncryl® portfolio

- Aqueous acrylic binders for the formulation of heat seal lacquers with low to high activation temperatures. These acrylic co-polymer emulsions provide a secure seal and show smooth peeling behavior. Applications range from sealing lacquers for dairy and pharmaceutical packaging to cardboard blister packaging and acrylic coated heatseal BOPP packaging films for confectionary, perfume and tobacco packaging.

- Pre-metallization primers for vacuum metalized paper substrates used in tobacco packaging and paper labels.

- Pre-print primers for hard and soft aluminum with excellent heat resistance.

- Print-primers for aluminum yogurt lidding providing heat and chemical resistance.

- For all above mentioned systems we offer a numerous additives to further improve the print quality.

Benefits of our water-based solutions include

- improved recycling through replacement of polyethylene coating

- non-fluorinated grease-barrier coatings

cost effectiveness compared to solvent-based systems

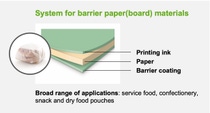

Joncryl® HPB – product line for liquid barrier coatings

High Performance (liquid) Barrier coatings for paper(board) packaging solutions

BASF’s Joncryl® HPB technology provides water-based polymers for use in coatings for functionalized paper(board) packaging applications. These food contact approved systems provide water, grease barrier and heat sealability properties similar to current PE extrusion coating layers.

Enables sustainable paper packaging with barrier and seal:

- Good barrier and heat seal properties, while still repulpable

- Flexibility in application methods (e.g. rod coater, gravure)

- Kit test results: >12

PE Replacement/liquid barrier

| Products* | Key properties | Application |

| Joncryl® HPB 4011 | excellent water barrier, heat sealable | Boxes and other food packaging applications |

MVTR

| Products* | Key properties | Application |

| Joncryl® HPB 1631/1633 | low MVTR and good blocking resistance | Paper bags and pouches for dry food, boxes for deepfreeze food applications |

| Joncryl® HPB 1634/1635 | low MVTR and good blocking resistance | Paper bags and pouches suitable for dry and fatty food packaging applications, partly based on renewable resources |

Grease and oil barrier

| Products* | Key properties | Application |

| Joncryl® 1632 | mineral oil and oxygen barrier, renewable content | Pouches and boxes for dry food applications |

| Joncryl® HPB 1700 | Improved flexibility and toughness | water-based primer to be used in combination with Joncryl® HPB 1701 |

| Joncryl® HPB 1701 | good creasing and folding resistance, heat sealable | water-based binder for excellent grease barrier coatings on paper/paperboard based materials |

* Specific food contact statements are available on request

Joncryl® HSL – product line for heat seal lacquers for use on film

Efficient solutions for high-performance water-based heat seal lacquers for plastic film

Offering a range of solutions for water-based heat seal lacquers for film applications, providing excellent sealing, optical and aroma barrier properties with good machinability. Typical applications are food packaging and outer wrap.

Key features & benefits of the portfolio:

- Broad global approvals for food contact applications

- Excellent seal strength and film clarity

- Low CoF, good blocking resistance

- Water-based technology

- Reduced solvent emissions

| Products | Key properties | Application |

| Joncryl® HSL 703 | low sealing threshold, low CoF, excellent film clarity, aroma barrier | BOPP packaging of confectionary, bakery and tobacco goods |

| Joncryl® HSL 704 | high solids, excellent seal strength | BOPP packaging of confectionary, bakery and tobacco goods |

Joncryl® HSL – product line for heat seal lacquers (aluminium foil and paper/paperboard)

Efficient solutions for high-performance water-based heat seal lacquers for aluminium foil and paper(board)

Offering a range of options for water-based heat seal lacquers in various applications, providing secure seal and smooth peeling behavior.

Key features & benefits:

- Broad global approvals for food contact applications

- Broad sealing and adhesion on different substrates

- Broad seal temperature range

- Good adhesion and printability

- Water-based technology

- Reduced solvent emissions

Heat Seal Lacquers for use on paper(board) and aluminium foil

| Products | Key properties | Application |

| Joncryl® HSL 9010 | good blocking resistance | cardboard blister packaging |

| Joncryl® HSL 9011 | low sealing initiation temperature | cardboard blister packaging |

| Joncryl® HPB 4011 | low sealing temperature, heat sealability and low COBB | paper and paperboard (PE replacement ) |

| Joncryl® HSL 9013 | good balance between heat sealabity and blocking resistance | aluminum pharmaceutical push-through blister packaging |

| Joncryl® HSL 9032 | excellent bond strength and easy opening | aluminum and paper/polyester lidding (sealed to polystyrene) |

| Joncryl® HSL 9055 | low temperature heat seal lacquer and corrosion resistance | aluminium cheese and chocolate packaging applications |

Joncryl® product line for primers (dairy lidding and lacquer applications)

High-performance water-based emulsions

for dairy lidding primer and lacquer applications

Ink receptive primers and lacquers for use on aluminium foil.

Water-based print primers offer broad over-printability with NC-solvent-based and conventional or LED-curing UV ink systems. Especially designed for use in aluminium dairy pot lidding applications – providing an excellent balance between resistance and ink receptive properties.

Key features & benefits:

- Good optical clarity

- Excellent adhesion to aluminium

- High gloss and heat-resistance

- Excellent adhesion with NC and UV inks

- Water-based technology

- Reduced solvent emissions

| Products | Key properties | Application |

| Joncryl® 1687* | Very high resistance properties in combination with UV ink adhesion | aluminium dairy lidding primer |

| Joncryl® 1689 | Improved production efficiencies due to lower temperature curing and/or faster line speeds | aluminium dairy lidding, pharma blisters and chocolate packaging |

| Joncryl® 1690 | High resistance properties in combination with UV ink adhesion. Good dispersion properties with TiO2 | aluminium dairy lidding primer |

| Joncryl® 1665 | Excellent heat resistance protective lacquer, low COF, clarity, high gloss | dairy products e.g. cheese packaging |

*amino cured systems

Joncryl® product line for primers (paper metallization)

High-performance resins and emulsions for paper metallizations

Primers for paper metallization for broad application in packaging. Especially designed for metal deposition under vacuum, they provide a smooth mirror-like metal surface and excellent intercoat adhesion.

Key features & benefits:

- Good film-forming properties

- Excellent adhesion of metal

- Good blocking resistance

- Good adhesion with different types of printing inks

- Good gloss properties

- Water-based technology

- Reduced solvent emissions

| Products | Key properties | Application |

| Joncryl® ECO 2177-E | good film forming properties, block resistance, gloss | water-based pre- and post metallization for e.g. paper inner liner and gift wrap |

| Joncryl® ECO 2189-E* | good gloss, block resistance | water-based pre- and post metallization for e.g. paper inner liner and gift wrap |

* used in combination with Joncryl® ECO 2177-E