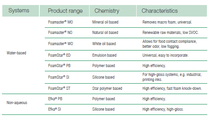

Formulators rely on BASF defoamer technologies to meet the most demanding standards of excellence – such as those in automotive coatings. Our lineup ranges from products based on mineral oils or native oils, specialty-emulsions and organosilicone-based solutions to silicone-free and star-polymer defoamers. The additives are defined by excellent foam suppression and micro-foam removal, high compatibility, long-term efficiency and easy handling in perfect balance. The range also includes solutions for environmental compliance such as low VOC, low SVOC and low odor foam suppressants.

Most defoamers are characterized by a delicate balance between compatibility and incompatibility in a given system. The active ingredient must be almost insoluble in the paint formulation, and able to form small defoamer droplets that migrate into the foam lamellae. To ensure long-term defoaming efficiency, the defoamer droplets need to remain stable in the system and not be absorbed or dissolved in storage. At the same time, a defoamer must be sufficiently compatible with the binder to ensure that no surface defects such as craters are generated in the final paint film due to incompatibility.

One of the outstanding innovations in the BASF defoamer portfolio is our award-winning FoamStar® technology. It is based on a hyper-branched polymer with a 3-dimensional star-shaped structure, containing hydrophilic as well as hydrophobic elements. Unlike conventional mineral-oil and silicone defoamers, our FoamStar® technology breaks down foam on a molecular level. It acts as a unique surfactant interacting with the foam-related surfactants and destabilizes the foam bubbles. When combined with conventional defoamer types, it accelerates bubble-break times and boosts efficiency.