Dispersions & Resins

Adhesive raw materials for furniture lamination

We want our homes and offices to look and feel good, today and tomorrow. Ensure the quality and longevity of your furniture – with water-based solutions that last.

Office chairs, sofas, kitchen or bathroom cabinets: furniture nowadays is as much an expression of individualism as they are everyday objects. Everyday objects that can be purchased at any time.

This creates several challenges for manufacturers of furniture around the world: products need to be readily available with short production and delivery times. On the lookout for their competitive advantage manufacturers provide ever changing designs and embrace new materials. All while offering stable, high quality products and finishes that last long and are both safe for humans and our environment.

To this end BASF offers a broad range of water-based adhesive raw materials that have been specifically developed for 3D lamination and for the formulation of foam bonding adhesives.

Please choose your field of application

3D Lamination

There are many good and viable alternatives to solid-wood furniture. But using these materials to their full potential often requires solidly bonded components. Make it stick – with our precursors for industrial adhesives.

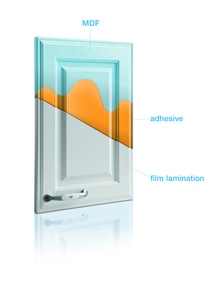

Kitchen and bathroom furniture are often made utilizing wood fiberboards coated with a plastic film. In its most common form this material is referred to as medium-density fiberboard or MDF. MDF can be formed with three-dimensional profiles and is usually thermo-laminated with hard PVC, PET or ABS films.

This leads to high requirements for the adhesives used in the lamination process: in order to ensure a perfect surface, they must neither contain flocking nor particles. Strong adhesion to the substrate and great cohesion are a must to prevent the film from peeling off and guarantee stable anchoring and long-lasting durability. To this end, adhesives based on polyurethane dispersions are used almost exclusively.

Requirements for high quality adhesives used in furniture, e.g. MDF lamination:

- Water-based

- Low activation temperature

(max 63°C and max 55°C high gloss) - High heat resistance (min. 80°C)

- Smooth surface

- High "green strength"

- Non-tacky

Luphen® products for feel-good homes

Thermoplastic polyurethane dispersions (PUD)

| Product | Main Properties | Good to know |

|

Luphen® 3615

|

|

|

|

Luphen® 3695 |

|

|

|

Luphen® D 207 E |

|

|

|

Luphen® 3685 |

|

|

All Luphen® products are available as a Biomass-Balanced product (BMB). |

||

Complementary products for feel-good homes

Acrylic dispersions and cross-linkers

| Product | Main Properties | Good to know |

|

Basonat® F 200 WD |

|

|

|

Basonat® HW 1180 |

|

|

|

Acronal® DS 3502 |

|

|

|

Acronal® 5400 |

|

|

Water based dispersions specifically developed for technical thermo lamination: our adhesive raw materials are especially suited for furniture adhesives due to their nearly instant setting properties, greatly reducing the risk of damaging the lamination during the opening process of the laminating press.

Foam bonding

Comfortable seating and furniture are often the product of an elaborate production process. Make it stick – with our adhesive raw materials for the manufacturing of matresses, upholstery and office furniture.

Gluing upholstery foam to various carrier materials requires special adhesives. Once applied the adhesive must not penetrate the open-pored material. To this end the foam-bonding dispersion coagulates whilst being sprayed onto the respective surface.

In the production of seating, sofas and office furniture specialized adhesive polymers are used. These foam and upholstery adhesives exhibit high levels of fast acting wet strength. In addition, they must be able to quickly absorb great tension and form a soft, non-noticeable glue line.

Ensure high productivity, fast processing and easy handling with our spray adhesives for upholstery and foam:

- High initial tack

- Long open time, allowing assembly up to 20 Minutes after spray-coating

- High "green strength"

- Soft and elastic adhesive line

- Good adhesion to common substrates

- No use of solvents / VOC / FA / APEO

Foam bonding solutions for feel-good spaces

Foam adhesive portfolio

| Product | Main Properties | Good to know |

|

Acronal® 3710 |

|

|

|

Acronal® 3657

|

|

|

|

Luphen® D DS 3548 |

|

|

|

Acronal® 5400 |

|

|

BASF offers a broad range of waterbased adhesive raw materials that have been specifically developed for the formulation of foam bonding adhesives. Our dispersion technologies are available for one- and two-component systems. The desired properties of each formulation can be fully customized with the help of our additives.

Let’s make it last, together.

Gerhard Vogel

Technical Expert Construction & Adhesives,

BTC Europe GmbH

Do you need more information about our adhesive technologies? Are you looking for samples of our dispersions? Looking for a reliable, long-term partner?

Our expertise for your industry: our teams offer unique insights into the production and processing of industrial adhesives and support you along the whole value and process chain:

- Formulation

- Technical Setup

- Handling

- Testing

- Certification