Dispersions & Resins

The BASF Joncryl® portfolio

Innovative solutions for more sustainable packaging.

We are dedicated to creating sustainable packaging solutions together with our customers. Whether you want to achieve lower carbon emissions, reduce plastic waste or increase the share of renewables in your product, our resins will help you do just that - without compromising on performance. Let's grab the chance to do this together and create better packaging for tomorrow!

Let's grab tomorrow. Let's get in contact.

We are here to identify products that help you to achieve specific sustainability goals, strengthen differentiation and enable regulatory compliance. We look forward to hearing from you!

Solutions along the product life circle.

Bio-renewable materials

With our Joncryl® BRC product line, you can formulate inks and coatings with increasing levels of bio-renewable raw materials, from 50 up to 64%.

Biomass balance approach.

For a significant product carbon footprint (PCF) reduction, BASF’s biomass balance approach can take you to net zero.

Our Joncryl® MB products make use of renewables for the production of our raw materials. They offer identical properties as their fossil counterparts in terms of formulation, quality, performance and food contact.

.jpg)

ChemCycling™ approach

Our ChemCycling™ approach enables the use of recycled plastic waste in our production process, saving fossil resources.

Water-based systems

We are convinced that water-based solutions are the future in packaging printing. With our Joncryl® portfolio for water-based inks, overprint varnishes and coatings, we offer a safer and healthier solution that performs as well as solvent-based systems. Plus, it also leaves you with a lower product carbon footprint (PCF).

For direct food contact, our Joncryl® HPB products give you much more freedom to create more sustainable, paper-based packaging. Our water-based high-performance barrier polymers help to create effective barriers for grease, mineral oil, water (vapor) and oxygen and are a great alternative to waxes and fluorocarbons.

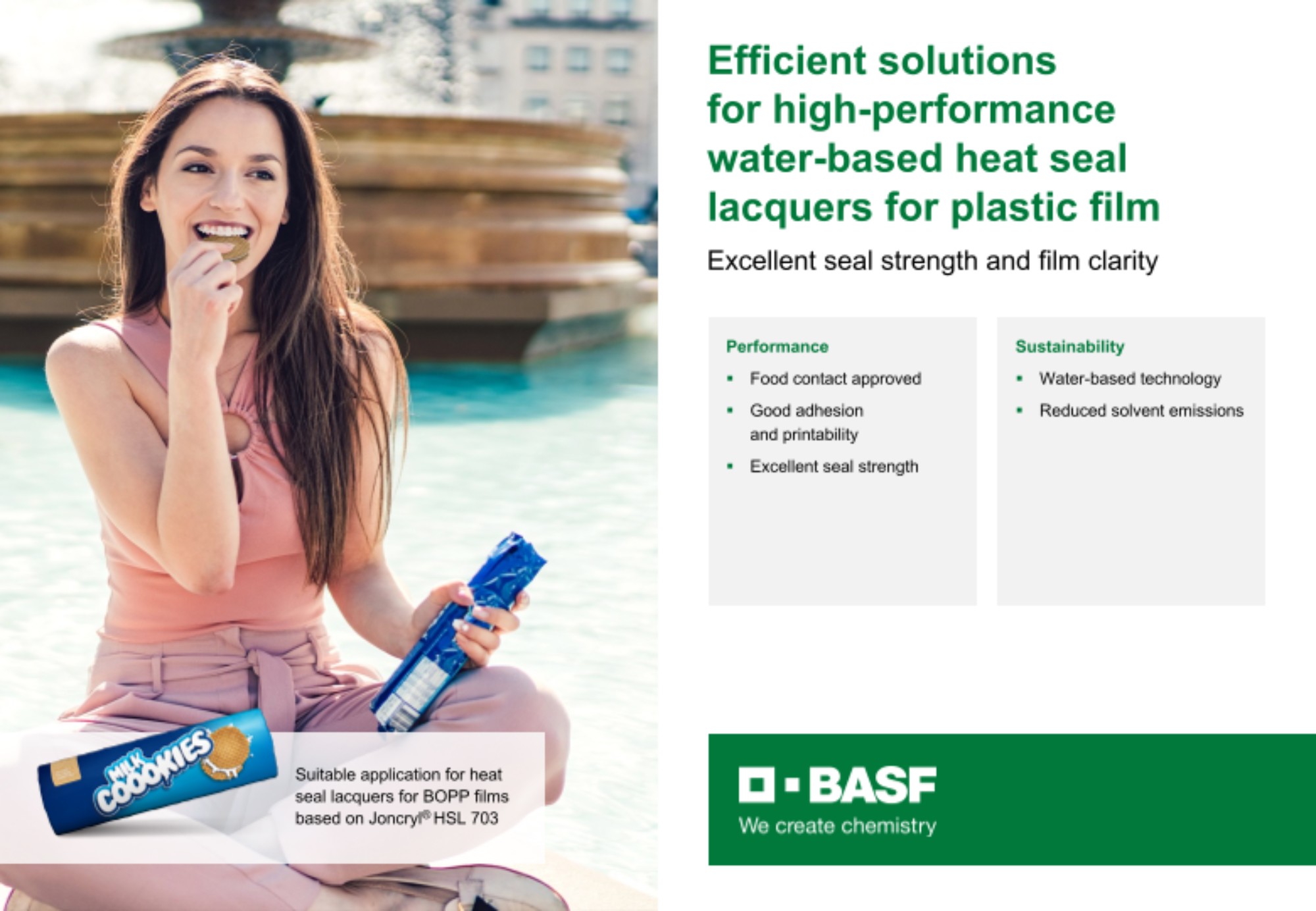

A perfect closure of paper and flexible packaging keeps produce fresh and reduces food waste. So have a look at our broad range of Joncryl® HSL binders for heat-seal lacquers to find the perfect formulation for this purpose.

Effective liquid printable barrier coatings created with our Joncryl® HPB range enable packaging to get recycled via the regular paper waste stream.

Our Joncryl® binders for water-based printing inks, overprint varnishes and coatings are fully recyclable.

Most of the printing ink and overprint varnishes (OPV) produced with our water-based binders for food packaging are certified for compostable packaging and evaluations for barrier coatings are ongoing.

Stay up to date and learn more

Sustainability Toolbox

PRETHINK INK